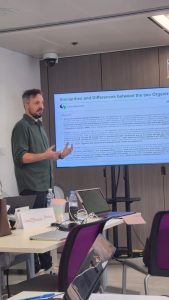

Phil Ramsdale, Technical Director for Thomas Storey Fabrications (TSF) Group, has given a presentation to a distinguished group of international business leaders in Hong Kong in early October. The presentation was part of Manchester University’s Global MBA programme, bringing together experts from various industries to discuss innovative solutions and best business practices. Phil focused on core strategies, specifically highlighting capacity planning, lean manufacturing, and continuous improvement methodologies – areas that have been important to Thomas Storey’s success over the years in the steel  fabrication industry.

fabrication industry.

During the presentation, Phil explored the concept of capacity levelling, a method designed to balance production demands and resource allocation. This technique not only promotes ethical workforce utilisation, ensuring that employees are neither overburdened or underutilised, but also improves inventory management. By maintaining a lean, constant flow of production, businesses can increase the quality and reliability of their outputs. These strategies are crucial for companies looking to remain responsive to market changes without compromising efficiency.

Another key focus of the presentation was the application of LEAN manufacturing techniques. The aim of LEAN practices is to minimise waste and maximise flow within the factory. By streamlining production processes and eliminating activities that do not add value, businesses can enhance both quality and dependability.

Phil emphasised the importance of empowering employees as part of this process, using GEMBA walks (from a Japanese term for “the actual place” where value is created) and multidisciplinary teamwork to assess and improve daily operations, encouraging all employees to take an active role in decision-making. Fostering this culture of continuous improvement not only enhances operational efficiency but also boosts morale and innovation.

Phil highlighted the value of Techniques such as Pareto analysis, and the Plan-Do-Check-Act (PDCA) cycle help keep teams aligned and focused. As well as tools such as Toyota’s A3 problem-solving technique that utilise Ishikawa diagrams and the 5Y methodology, as an effective way to identify root causes of production issues and create sustainable improvements. Phil’s participation in the Global MBA program reflects Thomas Storey’s commitment to innovation and excellence. These insights will undoubtedly continue to shape our operations, ensuring we remain at the forefront of the steel industry and sharing knowledge across UK manufacturing.

Techniques such as Pareto analysis, and the Plan-Do-Check-Act (PDCA) cycle help keep teams aligned and focused. As well as tools such as Toyota’s A3 problem-solving technique that utilise Ishikawa diagrams and the 5Y methodology, as an effective way to identify root causes of production issues and create sustainable improvements. Phil’s participation in the Global MBA program reflects Thomas Storey’s commitment to innovation and excellence. These insights will undoubtedly continue to shape our operations, ensuring we remain at the forefront of the steel industry and sharing knowledge across UK manufacturing.